Image Not Found: /images/works/milsan1.jpg

Image Not Found: /images/works/milsan2.jpg

Image Not Found: /images/works/milsan3.png

Image Not Found: /images/works/milsan4.png

Image Not Found: /images/works/milsan5.png

Image Not Found: /images/works/milsan6.png

Image Not Found: /images/works/milsan7.png

Milsan Elektronik

Position: PCB Designer Intern

Ankara, Turkey 🇹🇷

May 2024 - September 2024

Overview

At Milsan Elektronik, I worked in a fast-paced environment focused on electronic solutions for consumer appliances. The company specialized in designing and manufacturing high-quality PCBs for household products, emphasizing reliability and user safety.

My Role

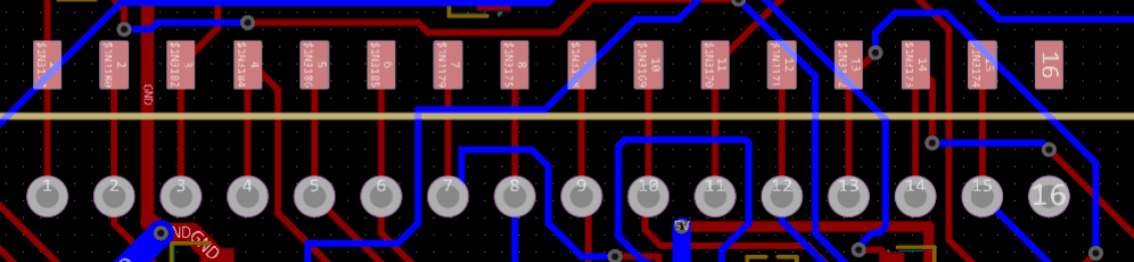

In May 2024, I joined Milsan Elektronik in Ankara, Turkey, as a PCB Designer Intern, eager to bring innovative solutions to everyday appliances. My first and second challenges were designing 2-layer PCBs for coffee makers and ovens, using HT66F004 (8MHz) and SC95F8523M28U (16MHz) microcontrollers respectively. I integrated transformerless full-wave rectifiers to convert 230V AC to 5V/18V DC, adding optocouplers for isolated power delivery to ensure safety and efficiency in these household devices.

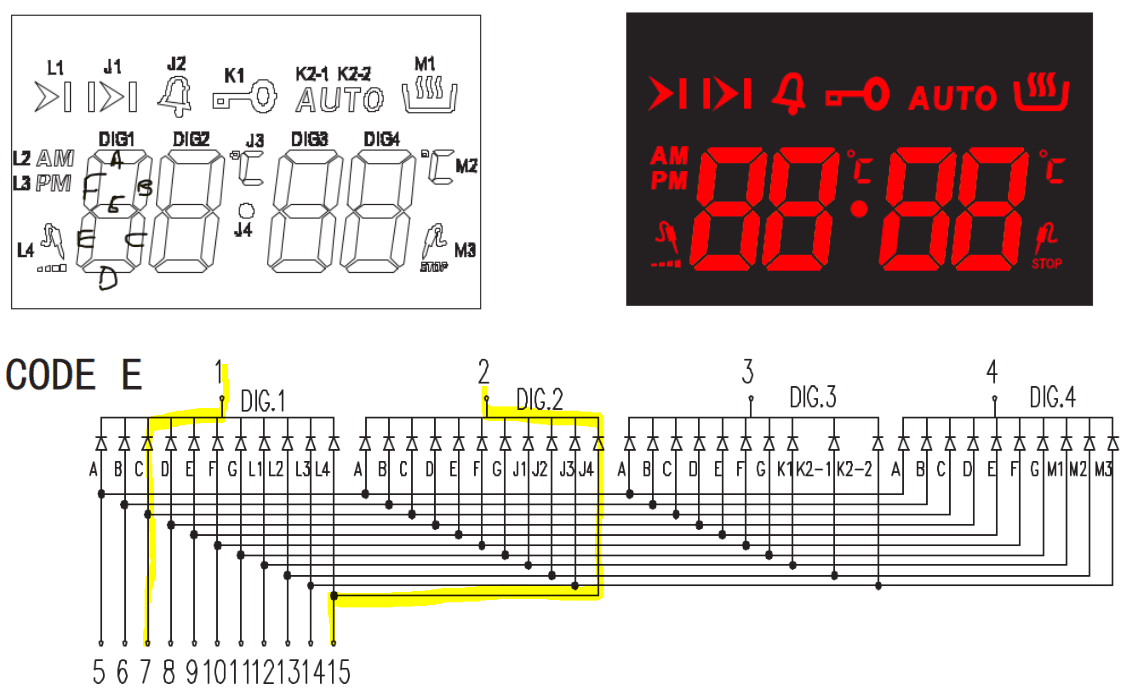

I wanted the oven to be intuitive for users, so I implemented 4 capacitive touch sensors and a 15-pin, 4-digit LED display integrated via SPI for user feedback on the oven card. For the coffee maker, safety was key — I added temperature and capacitive water level sensors to prevent dry operation communicated with UART communication interfaces, to make sure the device would protect users during every brew. Routing high-speed signals up to 16MHz was a technical hurdle, but I tackled it by applying impedance matching, carefully calculating trace widths, and using copper pours in power delivery areas for heat and current dissipation. With EasyEDA, I validated my designs through DRC and LVS checks, ensuring they were ready for production.

I built test benches and verified prototypes by measuring voltage/current at critical nodes using oscilloscopes, multimeters, and power supplies. This validated sensor inputs and microcontroller outputs (PWM, UART). Through iterative testing, we eliminated interference, improving reliability by over 25%. As an additional exploratory effort to enhance my skills, I delved into RTL concepts using Verilog through self-study simulations, applying them conceptually to potential FPGA integrations for future appliance upgrades. This complemented the main project by informing my approach to hardware verification.

Programming the microcontrollers in C and C++ was where I brought these devices to life. Using SoC programming tool developed by SinOne for SC95F8523M28U micrcontroller through JTAG interface and HT-IDE3000 developed by Holtek for HT66F004 microcontroller through 4-pin interface, I integrated PID controllers for precise temperature regulation, along with relay drivers and control systems to ensure the oven and coffee maker operated flawlessly. The final step was preparing everything for manufacturing — I developed schematic captures, BOM lists, Gerber files, and pick-and-place files, sourcing components from 15+ manufacturers and verifying component footprints against datasheets to guarantee compliance. By September 2024, I had successfully contributed to creating reliable and user-friendly appliances.

Skills Acquired

- Expertise in PCB design tools like EasyEDA for routing, validation, impedance matching, and DRC/LVS compliance

- Proficiency in low-level firmware programming with C, C++, and PID control implementation; conceptual knowledge of Verilog for RTL simulations

- Experience in hardware verification using oscilloscopes, multimeters, and power supplies for signal integrity and system debugging

- Collaboration in component sourcing, schematic development, and manufacturing preparation (BOM, Gerber, pick-and-place files)